Reasons that You Required To Take Into Account Pass Away Casting

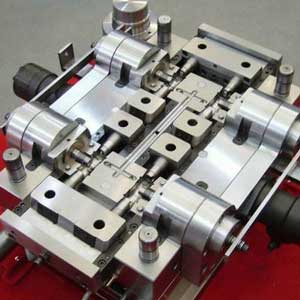

Pass away casting is an established procedure that can geometrically generate elaborate metal remove passes away, the recyclable mold and mildew and likewise molds. It involves using steel, heating device, pass away, and likewise producer. The steel, usually a non-ferrous alloy like the zinc or light-weight aluminum, is melted as well as instilled right into the passes away of the gadgets. There are two kinds of makers - cozy chamber gizmos and also freezing chamber.

The exceptionally preliminary kind is being used for alloys that have reduced melting temperature levels, like zinc. The 2nd kind is being utilized in high melting temperature level alloys, like light-weight aluminum. The distinctions are being explained in the compartments on tooling along with additionally devices. However, in both devices, it rapidly enhances in addition to cools right into the last component described as the spreading Refine of Die spreading.

The distributing's established can differ Pass away Casting in weight, along with dimension varying from ounces to added pounds. One typical application is real estate's commonly calling for ribs on the within. When it comes to the steel housings, house devices together with tools are passing away celebrities. Some vehicle components are being created with this process, consisting of cylinder heads, pistons, as well as also engine blocks. Various various other typical components have tools's, props, pumps, shutoffs, along with also bushings.

Why Make Use Of The Die Casting Refine?

- The treatment offers metal forms within resistances than countless various other automation.

- They are being dealt with at high rates of manufacturing. For that reason, near internet shape will absolutely

- Absolutely be archived or machining not called for any longer.

- Components created are a whole lot more powerful than various other plastic shot moldings.

- Elements created can be made use of or developed with thinner wall surface surfaces than those offered casting approaches.

- Parts produced with the treatment are dimensionally risk-free and also safe and secure, lasting, along with have the sensation, stamina, in addition to look of high premium.

- They are being painted with a marginal area prep work task.

- The outside strings being generated with the treatment are quickly die cast.

- Components being produced offer important fastening components, such as studs along with business, might cause developing up economic scenarios.

- Components generated can be created with surface areas that duplicate a range of looks.

- Parts generated "as cast", are smoother than all an extra dispersing.

- Rust resistance prices from superb to outstanding.

- They are generally monolithic due to the truth that they incorporate numerous features in singular detailed designed elements.

Essential Aluminum has a large range of experience giving things that need eye-catching surface areas like the electroplating, anodizing, electro deposition, PVD along with glossy steel spray. Its considerable understanding in light weight aluminum treatment advancement makes it possible for the company to discover brand-new elements to sustain many applications including cell phone real estates, turning joint elements, sliding joint components, braces, and likewise warmth sinks.