Uses as well as benefits of Precision casting

Modern Investment precision casting procedure has actually been in fact used in commercial production in the twentieth century forties. Throughout that time the progression of plane electric motors, call for suppliers such as blades, impellers, mist nozzles and also various other intricate form, dimension, accuracy and also smooth location of the heat-resistant blend parts. As the heat-resistant metal machining made complex, made complex shape components, which can certainly not and even challenging to use other procedures of manufacture, consequently, needed to have to discover a new preciseness in the producing procedure, therefore understand the old dropped wax passed on from precision casting, via to the materials as well as additionally Process Improvement, contemporary procedures of precision casting based upon the early craft was an important advancement. For that reason, the growth of the aeronautics industry to guarantee the request of precision casting, precision casting and likewise continuous improvement in addition to perfectness, yet additionally additional increase the performance of the air travel area has really produced advantageous problems.

China lives in the last century, the fifties and also sixties started Iron Casting for industrial development. In the future this advanced steel spreading procedure has in fact been remarkable development, one after another in the aerospace, automotive, maker devices, ships, interior burning motors, fuel generator, telecommunications devices, tools, health care tools and also decreasing resources and other production markets that are generally made use of, nonetheless furthermore for arts and also designs producing.

The claimed precision casting procedure, it merely is in fact to make use of fusible materials (consisting of wax or plastic) created of fusible designs (Rong mold and mildew and also mildew or design), on which the fireproof completing Ruogan layer of unique coating, drying in addition to setting after the accumulation of After a whole layer, as well as after that vapor or warm water originating from the melting of the covering style, as well as afterwards placed in sand container covering, complete of completely dry sand in the molding around it, as well as at some point forecasted in to the roaster in the warm calcination (consisting of greater strength shell, it can not create the shell after the removing straight baking), the mold and mildew as well as mold or even covering after toasting, after which putting liquified metal as well as are throwing.?

High viewpoint integrity of spreadings, frequently around CT4-6, of training course, steel spreading procedure as complex elements that influence the dimensional accuracy of dispersings much a lot more items such as mold and mildew and also mold diminishing, melting setting of contortion, heating in addition to air conditioning in the covering Variation of the line of product method, the mix solidification contraction as well as contortion of the spreading method, so the size of common economic investment castings accuracy are actually greater, however still call for to improve their congruity (utilizing in heat materials in the dispersing size wax uniformity to enhance the entire great deal).

One more conveniences of precision casting method is actually that it may be all kind of precision casting of difficult composite dispersing, precision casting unique high-temperature alloy castings can conveniently be. Like airplane electric motor blades, its modern account and also cooling down outside the dental caries, with the machining treatment basically hard. In addition to precision casting modern-day technology might not merely carry out automation, ensures congruity in spreading.

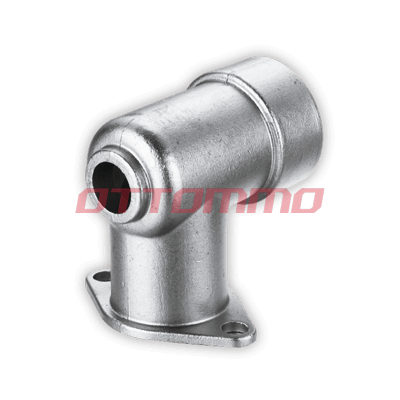

To understand more go here: Stainless steel casting