Favorable position of Precision Casting Method

Present day Investment precision casting technique has been linked in mechanical generation in the twentieth century forties. Around then the development of fly electric motors, need makers, for instance, sharp edges, impellers, spouts and also various other complicated shape, size, precision and also smooth surface of the heat safe composite parts. As the heat safe compound machining bothersome, complicated shape components, which can not or hard to use various strategies for manufacturing, accordingly, expected to situate an additional accuracy in the decoration procedure, so come to be aware of the old lost wax passed on from precision casting, via to the products and Process Improvement, present day methods for precision casting based on the antiquated art was an important innovation. Thusly, the innovation of the aeronautics organisation to advance the usage of precision casting, precision casting as well as continuous improvement as well as flawlessness, yet furthermore further boost the execution of the flight company has made positive conditions.

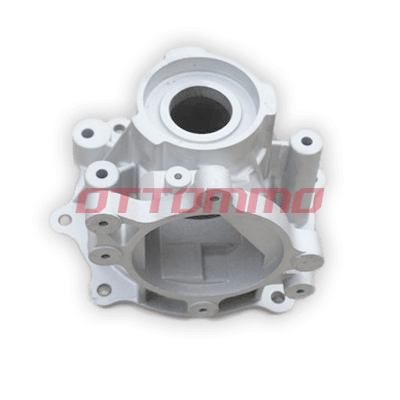

China is in the only remaining century, the sixties began casting for Stainless steel casting creation. Later this moved steel casting process has actually been massive renovation, in a constant development in the air travel, cars and truck, equipment tools, ships, internal burning motors, gas turbine, program interactions equipment, weapons, corrective gear as well as cutting tools and also other setting up organisations that are generally utilized, yet furthermore for expressions as well as artworks creating.

The alleged precision casting procedure, it essentially is to utilize fusible materials, (as an example, wax or plastic) made of fusible versions, on which the warm proof covering Ruogan layer of unusual covering, drying and solidifying after the development of After a whole shell, and afterward steam or boiling water from the liquefying of the covering version, and also afterwards embeded in sand box shell, packed up with completely dry sand in the trim around it, last but not least cast into the roaster in the heat calcination, (as an example, top quality shell, it can not mount the shell after the stripping direct preparing), the form or shell in the wake of simmering, after which pouring fluid metal as well as are casting.

High dimensional exactness of spreadings, mostly approximately CT4-6, certainly, steel casting process as uncertain components that affect the dimensional exactness of castings extra products, as an example, type shrinkage, softening approach of twisting, warming and cooling in the shell Variation of the line procedure, the substance hardening shrinking as well as disfigurement of the spreading treatment, so the span of common conjecture spreadings accuracy are greater, yet at the very same time require to boost their consistency (making use of in heat products in the spreading dimension wax consistency to improve the component).

Concealment of softening mode, the dental caries surface area get performed with using high-weight kind, thusly, dissolving mold and mildew surface area completion is usually high. Furthermore, an outstanding shell from the heat fastener and also headstrong product made into a warm proof covering Coating in Investment Scales and reached the liquid metal surface conclusion pit high. For this reason, the surface conclusions of castings accuracy castings than high, mostly as much as Ra.1.6 ~ 3.2 μm.

Casting the best centerpieces is there as a high dissolving mold and mildew casting dimensional precision as well as surface conclusion, it can lower the machining job, just to a minimal extent on the site requesting Leave a little machining compensation can be, and even some spreading simply remain powdering, cleaning up edge, can be utilized without machining. In this fashion, utilizing steel casting technique can save a large amount of machine device hardware as well as preparing time, generous mutual fund of metal products.

An additional beneficial position of precision casting strategy is that it extremely well may be a vast variety of precision casting of complicated substance casting, precision casting unusual high-temperature composite spreadings can be. As an example, stream electric motor sharp edges, its smooth account and also cooling outside the dental caries, with the machining procedure virtually unthinkable. With precision casting development can not specifically do large range manufacturing, guarantees uniformity in spreading.

For more details click on this internet link