A Complete Guide on Sand Casting – OTTOMMO CASTING

A Sand casting is used to make large parts (typically Iron, but also Bronze, Brass, Aluminum). Molten metal is poured into a mold cavity formed out of sand (natural or synthetic). The processes of sand casting are discussed in this section, include patterns, sprues and runners, design considerations, and casting allowance. The cavity in the sand is formed by using a pattern (an approximate duplicate of the real part), which is typically made out of wood, sometimes metal. The cavity is contained in an aggregate housed in a box called the flask. A core is a sand shape inserted into the mold to produce the internal features of the part such as holes or internal passages. Cores are placed in the cavity to form holes of the desired shapes. Core print is the region added to the pattern, core, or mold that is used to locate and support the core within the mold. A riser is an extra void created in the mold to contain excessive molten material. The purpose of this is to feed the molten metal to the mold cavity as the molten metal solidifies and shrinks, and thereby prevents voids in the main casting. In a two-part mold, which is typical of sand castings, the upper half, including the top half of the pattern, flask, and core is called cope and the lower half is called drag. The parting line or the parting surface is a line or surface that separates the cope and drag. The drag is first filled partially with sand, and the core print, the cores, and the gating system place near the parting line. The cope is then assembled to the drag, and the sand is poured on the cope half, covering the pattern, core, and the gating system.

The sand is compacted by vibration and mechanical means. Next, the cope is removed from the drag, and the pattern is carefully removed. The object is to remove the pattern without breaking the mold cavity. This is facilitated by designing a draft, a slight angular offset from the vertical to the vertical surfaces of the pattern. This is usually a minimum of 1° or 1.5 mm (0.060 in), whichever is greater. The rougher the surface of the pattern, the more the draft to be provided. The molten material is poured into the pouring cup, which is part of the gating system that supplies the molten material to the mold cavity. The vertical part of the gating system connected to the pouring cup is the sprue, and the horizontal portion is called the runners, and finally to the multiple points where it is introduced to the mold cavity called the gates. Additionally, there are extensions to the gating system called vents that provide the path for the built-up gases and the displaced air to vent to the atmosphere.

The cavity is usually made oversize to allow for the metal contraction as it cools down to room temperature. This is achieved by making the pattern oversize. To account for shrinking, the pattern must be made oversize by these factors, on the average. These are linear factors and apply in each direction. These shrinkage allowances are only approximate because the exact allowance is determined by the shape and size of the China casting. In addition, different parts of the casting might require a different shrinkage allowance. Sand castings generally have a rough surface, sometimes with surface impurities, and surface variations. A machining (finish) allowance is made for this type of defect.

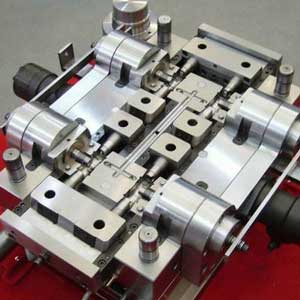

OTTOMMO Sand Casting plant has both manual and semi-automatic green/resin sand casting production lines for castings with various weight and geometries.

Click here to read about our other products-

Lost wax Casting China

Steel Casting China

Precision Casting China

Iron Casting

Die Casting

A Guide To The Investment Casting Process | Ottommo

As we began as an investment casting store, we comprehend information of this metal-forming technique. Investment casting is in addition described as lost wax spreading. Essentially, it explains make a wax pattern produced with a ceramic. Afterwards, defrosting the wax makes the ceramic vacant. At some point we acquire the spreading after pouring the metal into the ceramic. We remain to enhancing our treatment as well as utilizing the most current technology offered in our market. Investment casting is just one of the earliest steel working procedures recognized to guy. Continue reading to learn even more concerning copper investment casting as well as even more.

Investment Casting China is something you may not recognize much worrying, nevertheless regardless of that, it's something that has an unbelievable impact on our everyday lives. Yet originally, what is it? Investment casting, furthermore called lost-wax spreading, is a metal developing technique that dates all the methods back to old Egypt. Back then, beeswax was used to from a pattern, which was after that packed with the spreading material to supply steel elements boosted by a high degree of repeatability, accuracy, in addition to endurance. To this specific day, points have not modified too much - although primitive beeswax and also rudimentary steels have currently been transformed with more modern-day materials. Either technique, copper dispersing is where all of it began, in addition to just like it was a really essential treatment countless years back, it stays to be just that today.

Copper investment casting is predominately referred to as a go-to approach for sculpture as well as different other art types, but what's a little much less acknowledged is that copper alloy spreading has a selection of exceptionally helpful commercial applications too. Investment casting is an industrial treatment based on lost-wax spreading, among the earliest acknowledged metal-forming methods. The term "lost-wax spreading" can also describe contemporary investment casting processes.

Investment casting has actually been used in various kinds for the last 5,000 years. In its earliest kinds, beeswax was used to form patterns required for the spreading procedure. Today, advanced waxes, refractory products and specialist alloys are normally taken advantage of for making patterns. Investment casting is valued for its capacity to create parts with precision, repeatability, flexibility as well as likewise security in a variety of metals along with high-performance alloys.

The breakable wax patterns need to take on forces experienced during the mold and mildew and mildew making. Much of the wax utilized in investment casting can be retrieved and additionally recycled. Lost-foam dispersing is a modern kind of investment casting that eliminates specific activity in the process.

Visit The Website Click Here >> China Casting

Precision Investment Casting - Cast in More Than Just Stone, Cast in Metal!

Investment Casting is really one of the earliest widely known metalworking treatments around. Starting far more than 5,000 years earlier as "misused wax investment casting" the historic process made use of's wax to comprise a pattern which was in fact then used to make numerous elements as well as products.

Motivate ahead to today, 1000s of years later as well as the scientific research study remains to coincide. Nevertheless, investment casting builds around the world have actually introduced brand-new technologies such as modern waxes, evolved refractory parts, as well as the countless developments made it possible for by computer system systems along with desktop computer aided design.

The same to the results of our old ascendants when they did it, assigning provides unrivaled precision, repeatability, as well as top high quality-- this generates the investment casting of little parts as well as likewise massive elements in superb top quality compounds a terrific alternative to different other much less specific creating strategies.

The Investment Casting Process: An Overview

Design:

The investment casting technique starts with a style. This may be a drawing or an existing design part.

Develop Making The complying with step is really mold and mildew development. From an illustration, style, or design the investment casting foundry develops an injection mold. This wax pattern therapy mold is really then machined taking advantage of computer system helped design and/or individual computer assisted production, a marriage of both historic science as well as decreasing benefit modern-day innovation.

Wax Pattern Assembly:

Multiple wax pattern treatment mold and mildews are really set up on a plant or perhaps "sprue" to make up the overall component.

Layer:

In the complying with facet of the method, a ceramic layer and even prime slurry is connected to the plant or sprue, layer the Die Casting setting up in a great ceramic liquid. While the slurry is still damp, it is actually handled in an incredibly fine sand and also after that made it feasible for to dry before another slurry as well as also additional sand is utilized. This is in fact repeated up until there are actually 6 or perhaps more layers of ceramic layer on the wax setting up

Wax Removal:

Next off at the exact same time, the ceramic layers are intended for the wax installation to end up being cleared far from the within. This is made with an autoclave, where the ceramic layers are put on an owner as well as the autoclave utilizes vapor to thaw the wax inside the mold.

High Temp Burnout:

After wax is actually taken out the ceramic treatments experience a high-temperature tiredness to correct the ceramic molds. After this treatment they are readied for pre-heating as well as directing.

Steel Melting along with Casting:

In this step of the precision investment casting procedure, premium blends are melted in bordered heating systems. This activity is completely crucial to guarantee the Precision Casting high quality. In addition in this specific part of the method, degassing as well as alloying are executed to assure the thawed steel's houses are actually optimum for pouring. This metallic is actually then cast right into the ceramic mold and also mildew.

Cooling:

After cooling off, the Carbon Steel Casting takes the form of what was when the wax pattern. The moment the dispersing cools, the ceramic layer is eliminated together with greater powered water jets, leaving the spreading build with an established metal investment casting.

Trim, Grinding, as well as likewise Finishing:

Unwanted entrances desire that reduced off with a saw as well as more removed by grinding. This is followed by de-burring and also palm tooling, machining, in addition to completing causing a finished and additionally ended up spreading.

While this is actually one particular way investment casting is in fact brought out, there are similarly different other treatments of making spreadings-- like suction spreading, which is really usually utilized for Aluminum spreading. Just as the past of investment casting has really observed the treatment through numerous years of innovation, the technological advancements of the contemporary and additionally of throwing shops like Alcumet Incorporated remain to confirm that the process will certainly always number in the manufacturing of fixings, components as well as likewise products.

To understand even more click below: China Casting

Reasons that You Required To Take Into Account Pass Away Casting

Pass away casting is an established procedure that can geometrically generate elaborate metal remove passes away, the recyclable mold and mildew and likewise molds. It involves using steel, heating device, pass away, and likewise producer. The steel, usually a non-ferrous alloy like the zinc or light-weight aluminum, is melted as well as instilled right into the passes away of the gadgets. There are two kinds of makers - cozy chamber gizmos and also freezing chamber.

The exceptionally preliminary kind is being used for alloys that have reduced melting temperature levels, like zinc. The 2nd kind is being utilized in high melting temperature level alloys, like light-weight aluminum. The distinctions are being explained in the compartments on tooling along with additionally devices. However, in both devices, it rapidly enhances in addition to cools right into the last component described as the spreading Refine of Die spreading.

The distributing's established can differ Pass away Casting in weight, along with dimension varying from ounces to added pounds. One typical application is real estate's commonly calling for ribs on the within. When it comes to the steel housings, house devices together with tools are passing away celebrities. Some vehicle components are being created with this process, consisting of cylinder heads, pistons, as well as also engine blocks. Various various other typical components have tools's, props, pumps, shutoffs, along with also bushings.

Why Make Use Of The Die Casting Refine?

- The treatment offers metal forms within resistances than countless various other automation.

- They are being dealt with at high rates of manufacturing. For that reason, near internet shape will absolutely

- Absolutely be archived or machining not called for any longer.

- Components created are a whole lot more powerful than various other plastic shot moldings.

- Elements created can be made use of or developed with thinner wall surface surfaces than those offered casting approaches.

- Parts produced with the treatment are dimensionally risk-free and also safe and secure, lasting, along with have the sensation, stamina, in addition to look of high premium.

- They are being painted with a marginal area prep work task.

- The outside strings being generated with the treatment are quickly die cast.

- Components being produced offer important fastening components, such as studs along with business, might cause developing up economic scenarios.

- Components generated can be created with surface areas that duplicate a range of looks.

- Parts generated "as cast", are smoother than all an extra dispersing.

- Rust resistance prices from superb to outstanding.

- They are generally monolithic due to the truth that they incorporate numerous features in singular detailed designed elements.

Essential Aluminum has a large range of experience giving things that need eye-catching surface areas like the electroplating, anodizing, electro deposition, PVD along with glossy steel spray. Its considerable understanding in light weight aluminum treatment advancement makes it possible for the company to discover brand-new elements to sustain many applications including cell phone real estates, turning joint elements, sliding joint components, braces, and likewise warmth sinks.

Lost Wax Casting Process and its types - Ottommo Casting

Lost Wax Casting is a process in which an artist's sculpture is utilized to cast bronze. The Lost Wax Casting method is also known as Financial investment Casting in the modern industries. This is a very ancient approach used for casting little bronze sculptures, however today it is utilized to make many different artifacts as well as the process differs from factory to foundry. Today this established technique of Lost Wax Casting is used to make short articles like great jewelry, reveal pieces, dental restoration, a few specific commercial components as well as likewise some machine devices.

Process of Lost Wax Casting:

Rough Sculptor Making: An innovative musician makes an initial carver or mold or an artwork by using resources like wax, plaster or clay. A combination of oil based clay and also wax are favored as these products keep their softness.

Final Mold Making: A mold is then made based on the original sculptor. The mold is made up to 2 items and also a vital with shim is positioned in between the two items during construction so the mold and mildew can be placed accurately back with each other. Molds are normally used plaster or fiberglass or any other product that may be suitable. An internal mold and mildew of latex or plastic or silicone is put the pup preserve the information of the original artwork. Generally, the initial artwork constructed from plaster mold fractures as well as breaks during the first stage of deconstruction. Sometimes, numerable mold and mildews are required to get the precise reproduction of the initial artwork.

Filling out the mold: Once the latex as well as plaster mold and mildew is total and also ended up, molten wax is poured into the mold till it obtains an also finish around the mold and mildew. The thickness of the wax covering is around 1/8 inch. This procedure is then repeated until the preferred thickness is accomplished.

Removal of Wax Replica: The hollow wax replica of the initial artwork is then eliminated from the mold. The initial mold and mildew can be made use of for making more wax replicas, but because of the deterioration of the original mold the reuse of the mold is restricted.

Softening: Each wax mold and mildew is then chased or softened utilizing heated metal devices. The metal devices are rubbed around sections that show splits or the signing up with a line of the mold and mildew, where the items have actually come together. Independently shaped wax items are then heated up as well as affixed. The completed mold and mildew is after that worn order to conceal any type of flaws. The final piece after that appears like a bronze sculpture.

Making Paths For Molten Bronze: It is likewise called "spuring", in short the wax duplicate is after that branched with treelike wax, to ensure that the liquified bronze gets to the best components and likewise it aids the air to get away. The Lost wax Casting China crucial as well as careful spuring begins from the top of the wax duplicate. The top of the duplicate is affixed to by wax cyndrical tubes to various factors on the wax duplicate.

Slurry, fatigue, testing, putting, launch, metal-chasing, as well as painting are the last steps in the procedure of lost wax casting.

OTTOMMO Casting is a China Casting metal foundry with investment casting, die casting, sand casting and full in house CNC machining capabilities.

For further information please follow us : OTTOMMO CASTING

Investment Castings - Knowing Its Processes and Applications -Ottommo

Investment casting is one of the oldest forms of creating precision parts in metal. It is also known as the lost wax method. The process involves creating a wax pattern which is essentially a replica of the desired part in steel. The pattern is encased in a ceramic material and then removed or "lost" through the introduction of heat. The mold will then have molten steel poured into the opening. Once the mold is broken away from the solid steel, the casting is available for use.

The history of this process dates back thousands of years. Originally bees wax was formed into the desired shape and then covered in clay. Metal was melted using bellows and coal fire. The process was used to form shapes such as idols, jewellery, and art. As time progressed, advancements were made in the precision of the materials and processes to the point where extremely predictable results could be achieved. Dentists were some of the first users of investment casting on a more industrial level, utilizing the process to create fillings to be used inside the mouths of patients.

Advancements in the pattern making, wax, refractories, and melting equipment have resulted in processes that can hold extremely tight dimensional properties. Modern investment castings generally hold dimensions that are measured by a few thousandths of an inch per inch. This allows components to be made that often can be used directly from the manufacturer without subsequent machining. Worst cases allow the parts to be near net shape, which minimizes the amount of handling and processing to be completed on the casting. Users of these casting processes can also deploy the process to create parts that can be poured in thousands of different materials including steel, non-ferrous materials, duplex alloys, aluminium, iron, and more.

Applications of Investment Casting China have grown tremendously during modern times. Investment castings are used to create components in aerospace, transportation, material handling, pump and valve, food processing and more. Sculptures and original art also employ investment casting to create a metal version of an artist creation. Investment casting is also used to create medical implements and components used inside the human body.

The history of investment casting will continually be redefined through the advancement of materials employed in the process. Each passing year has shown that raw materials can be combined in such a manner that results in improvements of process and cost. Investment cast wax, ceramic, and alloys combined with improved equipment to produce castings on a high or low volume basis ensure that the process will be deployed well into the future.

For More Information Click Here >> Die Casting

A Guide To The Investment Casting Process | Ottommo

As we began as an investment casting store, we comprehend information of this metal-forming technique. Investment casting is in addition described as lost wax spreading. Essentially, it explains make a wax pattern produced with a ceramic. Afterwards, defrosting the wax makes the ceramic vacant. At some point we acquire the spreading after pouring the metal into the ceramic. We remain to enhancing our treatment as well as utilizing the most current technology offered in our market. Investment casting is just one of the earliest steel working procedures recognized to guy. Continue reading to learn even more concerning copper investment casting as well as even more.

Investment Casting China is something you may not recognize much worrying, nevertheless regardless of that, it's something that has an unbelievable impact on our everyday lives. Yet originally, what is it? Investment casting, furthermore called lost-wax spreading, is a metal developing technique that dates all the methods back to old Egypt. Back then, beeswax was used to from a pattern, which was after that packed with the spreading material to supply steel elements boosted by a high degree of repeatability, accuracy, in addition to endurance. To this specific day, points have not modified too much - although primitive beeswax and also rudimentary steels have currently been transformed with more modern-day materials. Either technique, copper dispersing is where all of it began, in addition to just like it was a really essential treatment countless years back, it stays to be just that today.

Copper investment casting is predominately referred to as a go-to approach for sculpture as well as different other art types, but what's a little much less acknowledged is that copper alloy spreading has a selection of exceptionally helpful commercial applications too. Investment casting is an industrial treatment based on lost-wax spreading, among the earliest acknowledged metal-forming methods. The term "lost-wax spreading" can also describe contemporary investment casting processes.

Investment casting has actually been used in various kinds for the last 5,000 years. In its earliest kinds, beeswax was used to form patterns required for the spreading procedure. Today, advanced waxes, refractory products and specialist alloys are normally taken advantage of for making patterns. Investment casting is valued for its capacity to create parts with precision, repeatability, flexibility as well as likewise security in a variety of metals along with high-performance alloys.

The breakable wax patterns need to take on forces experienced during the mold and mildew and mildew making. Much of the wax utilized in investment casting can be retrieved and additionally recycled. Lost-foam dispersing is a modern kind of investment casting that eliminates specific activity in the process.

Visit The Website Click Here >> China Casting